Ideal Timing for Stamped Concrete Resurfacing

Stamped concrete resurfacings are most effectively applied during specific weather conditions to ensure proper curing and adhesion. The optimal period generally involves mild temperatures, low humidity, and dry conditions. These factors help prevent issues such as cracking, uneven coloring, or surface defects. Timing also depends on regional climate patterns, but generally, late spring through early fall offers the most suitable weather windows.

The best temperature for applying stamped concrete resurfacings is between 50°F and 85°F. Temperatures outside this range can cause improper curing or surface imperfections.

Low humidity levels are preferred during application to prevent excess moisture from affecting the curing process and final appearance.

Rain or high moisture conditions should be avoided during installation and curing to prevent surface flaws and ensure durability.

Late spring and early fall are typically ideal seasons, providing stable weather conditions conducive to quality results.

Spring offers moderate temperatures and low humidity, ideal for resurfacings.

Summer provides warm, dry weather suitable for stamped concrete projects.

Early fall features cooler temperatures and lower humidity, favorable for surface durability.

Ways to make Stamped Concrete Resurfacings work in tight or awkward layouts.

Popular materials for Stamped Concrete Resurfacings and why they hold up over time.

Simple add-ons that improve Stamped Concrete Resurfacings without blowing the budget.

| Weather Condition | Optimal Timing |

|---|---|

| Temperature | 50°F to 85°F |

| Humidity | Low to moderate levels |

| Rain | Avoid during application and curing |

| Season | Late spring through early fall |

| Temperature Fluctuations | Minimize to prevent cracking |

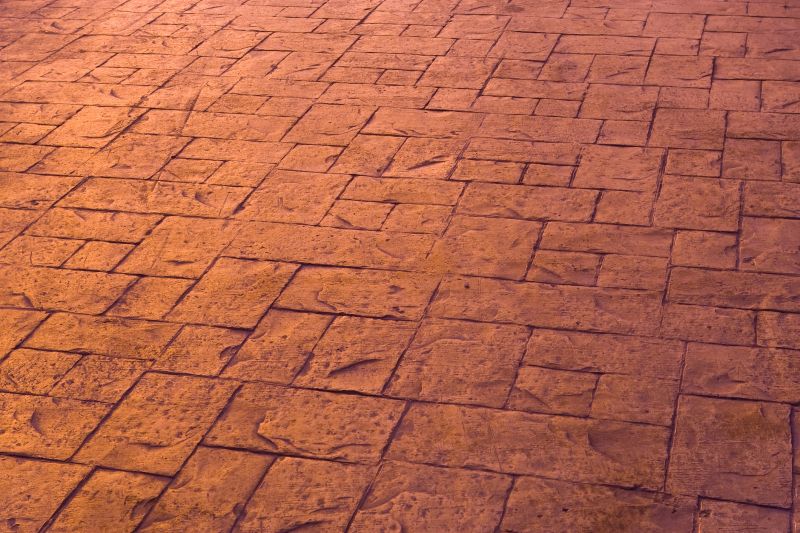

Stamped concrete resurfacings involve applying a decorative overlay that mimics natural stone, brick, or other textures. This process typically includes surface preparation, applying a thin layer of overlay material, and then imprinting patterns using specialized stamps. Proper timing ensures the overlay cures correctly, resulting in a durable, visually appealing surface. Studies show that when installed under optimal weather conditions, stamped concrete can last for decades with minimal maintenance, making timing a critical factor in project success.

The selection of the right season for stamped concrete resurfacings can influence the longevity and appearance of the finished surface. Proper weather conditions facilitate even curing and prevent common issues such as cracking, discoloration, or surface imperfections. Contractors often recommend scheduling projects during stable weather periods to achieve the best results and reduce the risk of delays or rework.

Detailed imprinting for aesthetic appeal.

Application during ideal conditions.

Durable and visually appealing.

Shows proper weather conditions during application.

High-end options that actually feel worth it for Stamped Concrete Resurfacings.

Finishes and colors that play nicely with Stamped Concrete Resurfacings.

Little measurements that prevent headaches on Stamped Concrete Resurfacings day.

A 60-second routine that keeps Stamped Concrete Resurfacings looking new.

A frequent mistake in Stamped Concrete Resurfacings and how to dodge it.

Small tweaks to make Stamped Concrete Resurfacings safer and easier to use.

Lower-waste or water-saving choices for Stamped Concrete Resurfacings.

The short, realistic tool list for quality Stamped Concrete Resurfacings.

Interested in stamped concrete resurfacings? Filling out the contact form can provide additional information and start the process for scheduling a project during the optimal season for best results.